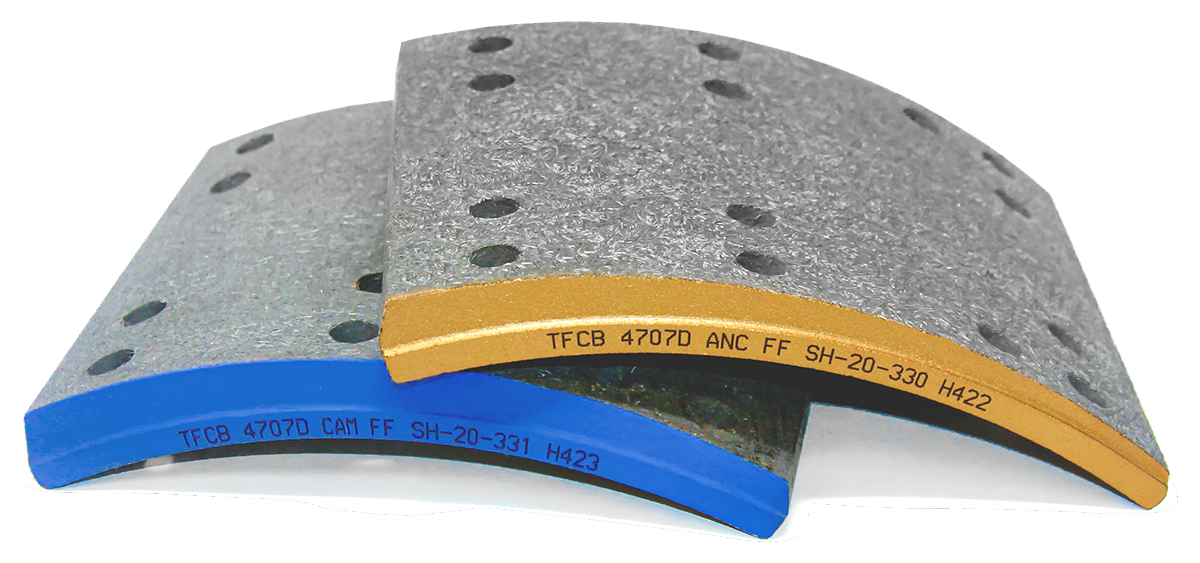

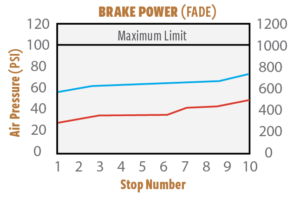

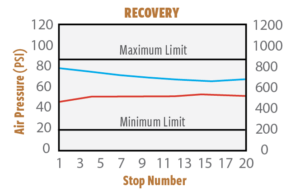

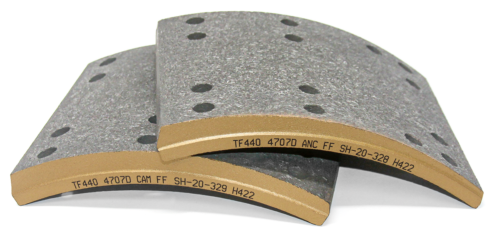

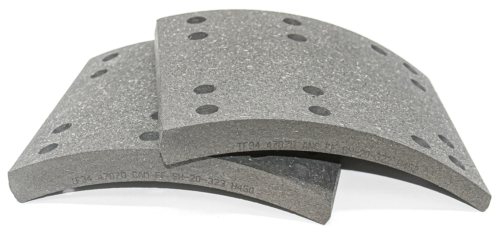

FORMULATION: Pairing the punch of an aramid fiber base block with the power of a semi-metallic, this brawny OTR combo resists brake fade in heat or water for the ultimate performance brake lining.

APPLICATION: For use on trucks, tractors and trailers in most applications, such as general cargo, stop ‘n go urban routes, bus, grain, liquid haulers, dump trucks, and lowboys.

CASH FLOW ADVANTAGE: TFCB linings are available in quantities less than a truckload, ship in 2 days to continental U.S. and free working capital and storage space to improve operations and profitability.

Questions? Email info@trilogyfriction.com or call us at 1-480-401-1589.