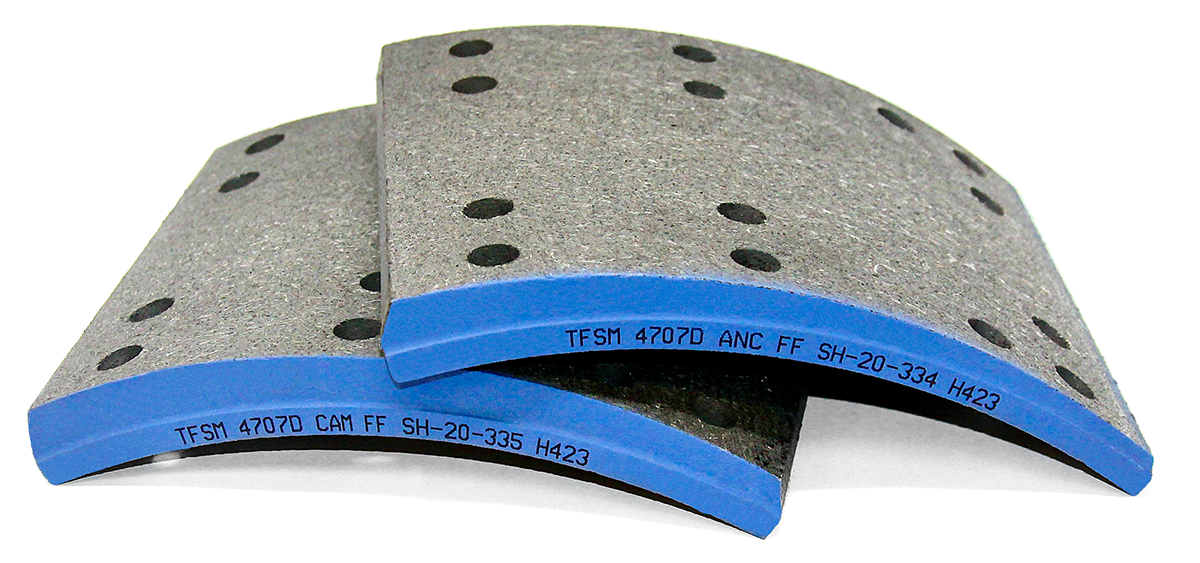

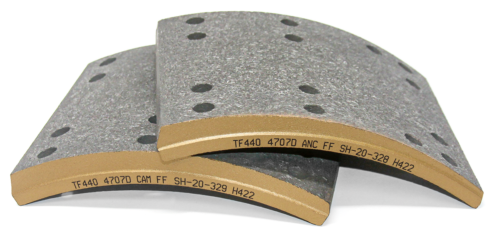

FORMULATION: Formulated for extreme heat and the grit-and-grime of off-road hauls, this high-density semi-metallic guards drums and wheel-end components for longer life.

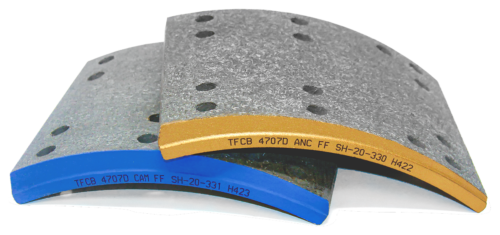

APPLICATION: When semi-metallics become too aggressive, this unique one steps in to deliver on trucks, tractors and trailers in most applications, such as general cargo, stop ‘n go urban routes, bus, grain, liquid haulers, dump trucks, and lowboys.

CASH FLOW ADVANTAGE: TFSM linings are available in quantities less than a truckload, ship in 2 days to continental U.S. and free working capital and storage space to improve operations and profitability.

Questions? Email info@trilogyfriction.com or call us at 1-480-401-1589.